What Products Use Thermoforming? 15 Vacuum Forming Examples

While thermoforming and vacuum forming are well-known processes for producing high-quality plastic parts, we find that many manufacturers are not aware of just how versatile this method can be.

To showcase the variety of components that can be made with vacuum pressure forming, we’ve compiled 15 examples of thermoformed products—some of which might surprise you!

1. Body Panels: Hoods, Roof Assemblies, Fenders, and Doors

2. Instrument Panels and Cockpits

4. Drip Pans

5. Belt and Chain Guards

6. Parts Trays

7. Inflow Preventers (Manhole Inserts)

8. Air Ducts, Flanges, and Adapters

9. Serving Trays

10. Medical Supplies

11. Public Transportation Panels

12. Pile Caps (Post Caps)

13. Kitchen Appliance Components

14. Furniture

15. Remote-Controlled Toys, Drones, and Unmanned Aerial Vehicles

1. Body Panels

Machine body panels, hoods, covers, and doors may look like they’re made from metal or fiberglass—as they used to be—but today, they’re often made from thermoformed plastic. You’ll find such body panels on the following types of machinery:

- Construction machinery and vehicles

- Agricultural equipment

- Lawn and garden machinery

- Material handlers

- Floor sweepers

We’ve previously analyzed the advantages of plastic over fiberglass in general practice, but for body panels specifically, fiberglass (and metal) has fallen out of favor because thermoplastics offer significant benefits, including lower production costs, lighter weight, and better sustainability.

One of the most appealing advantages of thermoformed body panels for machinery manufacturers is that they don’t require the same effort to maintain an excellent surface finish as fiberglass and metal do. The color and surface treatment (glossy or textured) of vacuum-formed parts are “molded in” during production. In other words, these characteristics are inherent to the plastic itself, so manufacturers don’t need to paint the parts. This benefit also extends to end-users; thermoplastic body panels have extremely high impact and scratch resistance, which would typically require dent repair or repainting in other materials.

2. Instrument Panels and Cockpits

Attractive and durable thermoformed instrument pads and dashboards are widely used in automotive, marine, all-terrain vehicle, and equipment applications. While small, high-volume parts are often injection molded, larger components are typically thermoformed for the following reasons:

- Large parts are generally better suited to thermoforming than injection molding.

- These components often have textured or “haircell” finishes; as we saw with body panels, thermoforming achieves this effect very easily.

- Since all components of a dashboard or console are made from the same material, matching is straightforward.

- Additional features, such as threaded inserts and slots for cutouts, can be added during production.

- Thermoformed dashboards are well-suited for soft-touch wrapping or painting.

3. Skylights and Vents

White polycarbonate skylight domes on building roofs

Polycarbonate is transparent and strong, making it an ideal material for skylights and vents, especially where glass isn’t feasible. Polycarbonate has excellent thermoformability, and for these products, the thermoforming process is particularly suitable because it induces minimal stress during forming, extending the window’s lifespan, and requires no contact with the mold surface, resulting in a smooth, clear finish.

4. Drip Pans

Outdoor air conditioning unit compressor mounted outside a building

Due to their large size, drip pans for household appliances, HVAC equipment, pet crates, pump systems, and other water-catching applications are often manufactured using thermoforming. Thermoforming molds are relatively inexpensive, making it ideal for producing large components (whereas injection molds for large drip pans would be prohibitively expensive). Thermoformed drip pans are strong, flexible, recyclable, chemically resistant, and can be molded with drain holes or other features.

5. Belt and Chain Guards

From generator belts and all-terrain vehicle guards to fitness equipment and bicycles, belt and chain guards for various products benefit from thermoforming due to:

- Very low mold costs for these products.

- Easy addition of other features to the mold.

- Thermoplastics used for guards that are weather-resistant, tough, and aesthetically pleasing.

- Guards that can be easily fabricated for hardware installation.

- Materials that provide high levels of injury protection at low cost.

6. Parts Trays

Manufacturing plants and assembly lines use specially designed trays (or “dunnage” containers) to keep parts organized during manufacturing, packaging, and shipping. You can produce custom-sized and designed trays cost-effectively with vacuum forming, and the thermoplastic materials are tough enough to withstand multiple handling cycles while being recyclable!

7. Inflow Preventers (Manhole Inserts)

Often called “manhole cover inserts,” inflow prevention disks are devices that limit or prevent uncontrolled groundwater from entering municipal sewer systems and overwhelming wastewater treatment plants. Since multiple sizes of inflow preventers are often needed to effectively block rainwater from sewers, manufacturers typically choose thermoforming because of its low mold costs and robust, reliable materials.

8. Air Ducts, Flanges, and Adapters

Thermoforming offers an efficient solution for adapting ventilation and airflow ducts to different equipment, sizes, and shapes. Multiple parts can be formed simultaneously, and after trimming, they can be assembled into complex adapters using adhesives, hardware, or ultrasonic welding. This process allows for low-cost production of intricate adapters, such as square-to-round transitions, angled adapters, or flanges, making it ideal for solving complex transition challenges. Additionally, thermoformed ducts and adapters can feature durable, weather-resistant finishes to meet both functional and aesthetic needs.

9. Serving Trays

Thermoformed trays made from durable high-density polyethylene (HDPE) are commonly used in carts and display racks because they are cost-effective, reliable, and require minimal maintenance for both indoor and outdoor use.

10. Medical Supplies

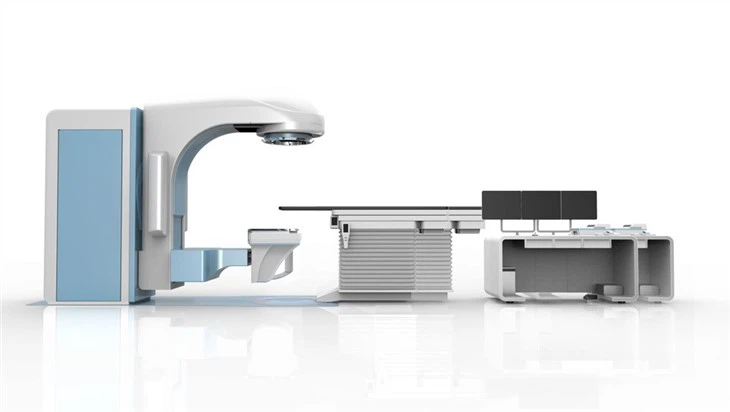

While many plastic products in the medical field are injection molded, thermoforming is also widely used to produce instrument housings, imaging equipment enclosures, hospital furniture and bed components, testing carts, and medical waste containers.

11. Public Transportation Panels

Panels on buses, airplanes, subway cars, and trams—including wall panels, furniture, and door and window trims—are often produced using thermoforming. Materials can be selected to minimize scratches and wear, resist graffiti, require almost no maintenance, and be easy to remove.

12. Pile Caps (Post Caps)

Piles, fence posts, and even utility poles must withstand long-term exposure to weather and animal perching like birds. Over time, these factors can cause significant damage, but thermoformed products for this purpose are extremely durable, often lasting over a decade even in direct sunlight and harsh weather. These plastic caps are easy to install, flexible enough to fit irregular post shapes, customizable in various forms, and provide excellent protection at a fraction of the cost of replacing piles or poles—saving hundreds or even thousands of dollars.

13. Kitchen Appliance Components

It’s well-known that refrigerators often feature thermoformed liners, but many other items in the kitchen can also be made with thermoforming:

- Silverware organizers

- Produce bins

- Blender and chopper housings and lids

- Serving platters

Many popular mixing, slicing, and other cooking and food preparation appliances are thermoformed (or feature thermoformed housings or lids) to reduce weight and make them easy to clean.

Thermoforming offers two major advantages for medical supplies:

- Thermoplastic materials are easy to clean and disinfect, making them ideal for environments with strict hygiene standards.

- Vacuum-formed parts with textured surfaces are easy to achieve, making objects easier for healthcare workers and patients to grip.

14. Furniture

Many common furniture pieces can be made with thermoforming, most notably the molded plastic chairs used in schools and events, as well as:

- Stadium seating

- Upholstered chair backs

- Tables

- Armrests

- Dressers

- Vanity tables

Advantages of thermoformed furniture include:

- Producing large, functional furniture components at reasonable cost and high reliability

- Resistance to rust and rot (unlike metal and wood)

- Easy coloring and decoration

- Strong weather resistance and UV protection

- Lighter than wood, metal, and fiberglass

15. Remote-Controlled Toys, Drones, and Unmanned Aerial Vehicles

Thermoforming can create lightweight, strong, impact-resistant housings for remote-controlled toys, vehicles, and drones often used for recreational activities. Drones may even need to withstand extreme environmental conditions (such as those used for monitoring storm damage at weather stations)—and thermoplastics are up to the task!

Get Custom and Stock Thermoformed Products

Thermoforming has some significant advantages in product manufacturing. If you look at the product examples we’ve listed, you’ll notice some common themes, such as:

- Cost-effectiveness

- Ideal for large parts

- Flexible design options

- Easy customization

- Low maintenance

- Sustainable and recyclable

- Durable and weather-resistant

- Lightweight yet strong

While thermoforming certainly can’t be your only production process, you might be able to use it more than you currently do. Are any of the products shown here made using other methods in your operations? If you’re interested in switching to thermoforming, contact us—we’re ready to help you find the right process and materials for your project.