Molding Processes for Drones Using Carbon Fiber Composites

In the design and manufacturing of drones using carbon fiber composites, structural elasticity and stiffness distribution are often achieved by adjusting layup angles and the number of material layers. Carbon fiber composites are among the most commonly used reinforcement materials in drones, typically manufactured using three molding processes.

Vacuum Bag Molding Process

Compared to autoclave molding, the vacuum bag molding process is simpler, requires lower initial investment, and is moderately easy to operate. However, it provides lower pressure, making it suitable only for composite components with less stringent quality requirements, such as honeycomb sandwich structures and laminates up to 1.5mm thick. Due to its cost advantage, this method is widely used in low-speed drone manufacturing, meeting the production needs of most parts for small, low-speed drones.

In practice, vacuum bag molding involves processes like prepreg layup or wet layup. Wet layup is prone to human-induced inconsistencies, such as uneven resin application, particularly in sandwich structures. Improper brushing direction can also cause fiber distortion, compromising the stability of the manufactured component. Using prepreg layup effectively mitigates these issues, enhancing component stability.

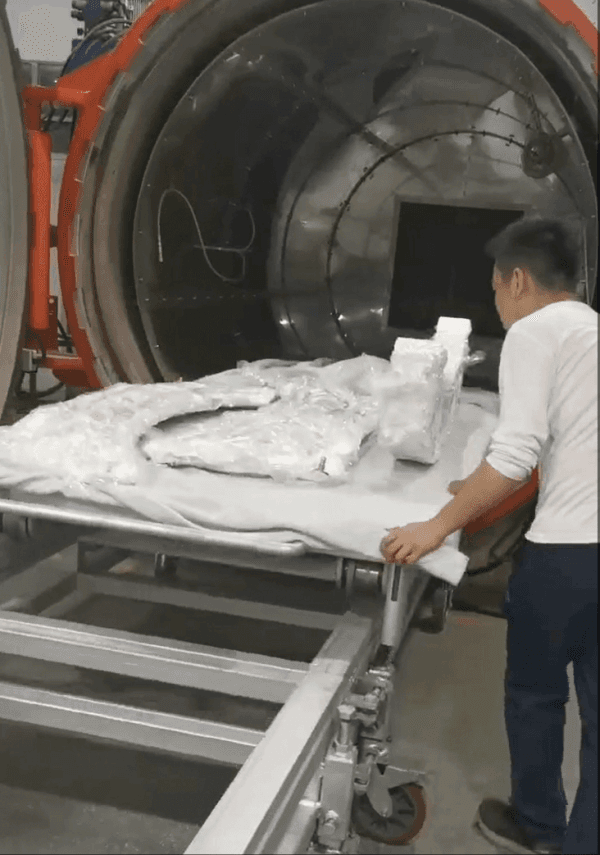

Autoclave Molding Process

Autoclave molding is a high-performance composite molding process. For drones requiring high speed, composite components and primary load-bearing structures are often manufactured using this method. Autoclave-molded carbon fiber composite components exhibit superior internal quality, uniform resin content, and excellent mechanical properties.

However, autoclave molding has drawbacks. It demands high equipment standards, leading to significant initial investment and processing costs, making it less economical. For budget-constrained projects, low-temperature, low-pressure molding techniques are often preferred. Additionally, during autoclave molding, resin flow, heat transfer, chemical crosslinking, and void formation interact, increasing process control complexity. Errors can result in defects like resin starvation or high porosity.

To ensure the quality of drone components, simulating kinetics, resin flow, and heat transfer during autoclave molding allows precise control of pressure and temperature curves based on model data.

Compression Molding Process

Compression molding is well-suited for manufacturing foam sandwich composite components. It combines the advantages of autoclave and vacuum bag molding, offering high production efficiency, significant molding pressure, moderate equipment investment, and good cost-effectiveness. Drone control surfaces with foam sandwich structures are typically produced using this method. In carbon fiber drone wing production, compression molding ensures wing surface quality and airfoil precision, enhancing overall drone manufacturing quality.

Conclusion

The application of carbon fiber composites is a key trend in drone manufacturing, effectively meeting requirements for range, flight duration, altitude, cost, and stealth. Optimizing structural design and manufacturing processes for carbon fiber composite drones is critical. The former relies on drone designers’ efforts, while the latter requires continuous innovation in the development and application of carbon fiber composites.